About Recycled Material

Plastic: A special material

Plastic probably doesn’t strike you as something special. But there isn’t any other material that is so strong and so light. And that protects valuable things so well, even though you can see right through it. And then plastic also lasts a really long time.

Strong and light

Because plastic is strong and light, it’s ideal for production and transit. What’s more, you don’t need that much of it in relation to the product that you want to protect, particularly when compared to other packaging materials.

Optimal protection

Plastic is the perfect barrier protecting the packaged product from external environmental factors. Plastic is a material that protects products against damage from oxygen, CO2, and other airborne agents. That means that things keep well for a long time.

Durable

Plastic lasts a long time. However, plastic waste is often still stored underground or incinerated, or worse, it ends up in the environment. By making it into a resource again, plastic can be used anew, over and over.

Many types

There are many different types of plastic, each with its own special characteristics, suitable for various different uses. There’s choice enough, therefore, for protecting numerous different kinds of products (and: to be attractive while doing so!).

In comparison with other packaging materials

It's clear what the advantages are with plastic...

Collection and recycling

Luckily, the waste disposal system of the Netherlands functions relatively well, and most materials are properly recycled and re-used as new resources. Recycled plastic can also be used as a new resource, but currently the market is not making sufficient use of this. The techniques for recycling waste plastic are developing rapidly and getting better every day. It’s now up to producers and consumers to start choosing recycled material instead of new plastic. For a sustainable circular plastic chain

In Nature

The estimated degradation of materials in nature:

- Cardboard drink or milk carton: 2-3 months;

- Soda cans of aluminium: 200 years;

- Plastic: 500 years;

- Glass jars and bottles: 1-2 million years

The degradation of these materials will take months or years. The more important it is that our waste is collected properly, so that it will not roam around in nature for years.

CO2 footprint

Plastic packing, like cardboard packaging, has a relatively small carbon footprint. Plastic packaging is light and thin-walled. Only a little of the material is necessary, and also not much energy is needed for production and transportation per package. That means that plastic packaging’s CO2 footprint is quite a bit smaller than, for example, that of glass packaging.

At ‘Milieu Centraal’ you can find more information about the environmental impact of different packaging materials.

A sustainable choice?

Would you like to know what the most sustainable choice is for your product? That depends completely on the properties and storage life of the product that you want to sell, transport, protect and/or prolong the usability of.

It would be really great for plastic if, in the future, we could make sure that plastic didn’t end up in the environment any more, and if we could clean up the plastic that is there now. In addition to that, it would also be great if more and more companies and consumers were to choose recycled plastic instead of non-recycled plastic. That way plastic waste becomes valuable again, and plastic becomes the more sustainable choice.

“It’s time that we start looking at plastic as a valuable material instead of as something without value.”

Then plastic waste would be use again as a resource for new products.

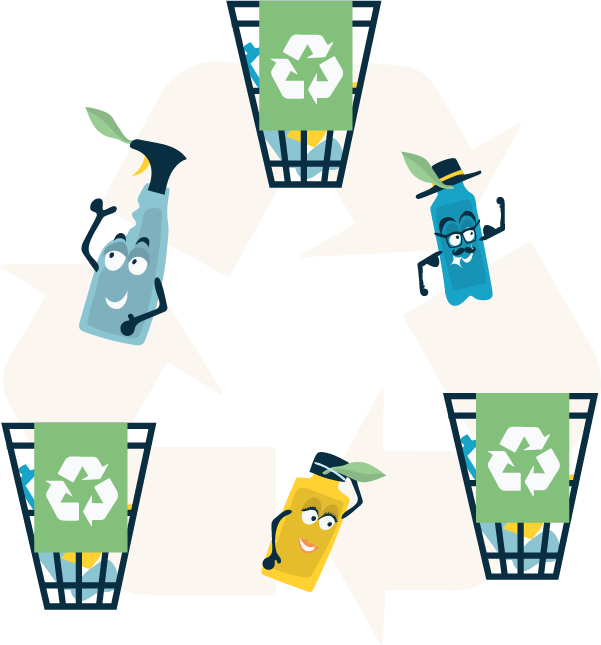

Types of plastic bottles

We can differentiate two different groups of plastic materials: thermosets and thermoplastics. Thermosets are plastics that harden after having been heated, meaning their shape can no longer be changed. Such plastic disintegrates and burns if it is heated again. The thermoplastics, used to make bottles and other things, are different. These plastics liquefy again when they are heated and can be formed into new shapes. Moulds can be used to make new bottles, making thermoplastics, and thus bottles, perfect candidates for recycling.

Pet: For transparent bottles

You know PET (polyethylene terephthalate) from the familiar PET bottles. That’s what we use PET for too. The clear and transparent properties of PET ensure that you as consumer can see what’s in the bottle. In addition, it forms a good barrier, it’s unbreakable, and is suitable for labels, sleeves or imprints.

HDPE: For non-transparent (opaque) bottles

HDPE (high density polyethene) is used for non-transparent bottles; it also has good elasticity, making it perfect for squeeze bottles. Shampoo bottles are almost always made from this material. Because pigments can be added to HDPE, you see it in every colour of the rainbow. It would actually be better for recycling if no colours were added and the base natural colour kept instead.

PP: for Caps

PP (polypropylene) is a fairly stiff material, making it very suitable for closures and caps. PP is also a perfect material for recycling.

What’s the story with bioplastics?

What are bioplastics, anyway?

Bioplastics may mean plastics made from organic material* or plastics that are biodegradable.

*Organic material such as starch from corn, potatoes, coconut or sugar-cane, or cellulose from wood or sugar-cane. or cellulose from wood or sugar-cane.

Not always biodegradable

The basic resource used to make this kind of plastic is a renewable natural material. The opposite is true of ‘regular plastics’, which are made from fossil fuels such as petroleum, crude oil or coal. These are limited. This doesn’t necessary mean that all bioplastics are biodegradable.

Bioplastics may have natural origins yet still react ‘normally’ like all other types of plastic when they end up in the environment.

Bio-based / biodegradable / compostable

Different terms for talking about bioplastics and yet each one means something slightly different. If a bioplastic is bio-based it doesn’t necessarily mean that it is also biodegradable or compostable. And biodegradable can also be made from oil.

Learn more about bioplastics? Read this report from the WUR (Wageningen UR) Bio-based and biodegradable plastics – Facts and Figures

From waste to resource

After waste has been sorted by the consumer, it goes to the waste sorting plant where it is further sorted. For plastic this means films are separated from thicker plastic packaging, and PET is separated from PE (HDPE and LDPE) and PP. Thicker plastics go to special treatment plants to be further recycled. What happens to it? Here’s an example of what happens to PE:

The sorted plastic is chopped into to pieces of 5 by 10 cm (‘shred’).

A magnet pulls out any metals, and water is used to get out any stones or glass.

Grinding mills grind the shred into even finer flakes with a maximum of 1 x 1 cm. Then the material is washed in cold water and dried, followed by a warm wash and cold rinse.

Air is used to get out any remaining film, and darker plastic is separated from lighter with the aid of cameras.

The finely ground flakes are mixed together to form a homogeneous mass, and then ‘salt and pepper’ (such as pigments) are added.

The flakes are melted and filtered to remove impurities, and the melted mass is put through a kind of meat-grinder and comes out as grains.

This granular material is put through a sieve to separate the finer grains from the coarser ones, which are then of course recycled again.

The ultimate result: a recycled material that is similar to new plastic in terms of its properties and can be put back into the plastic chain.

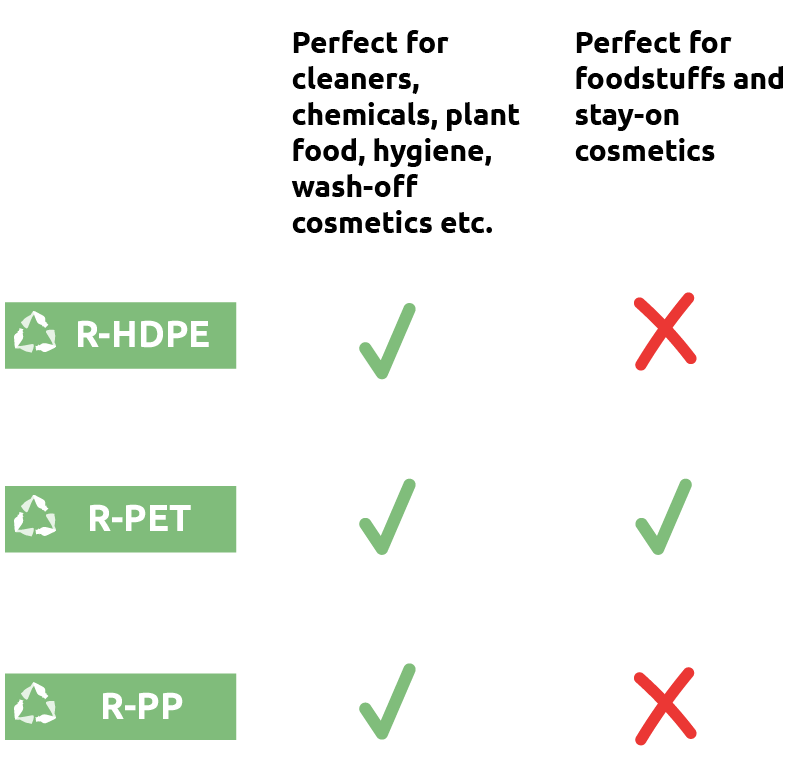

The properties of recycled plastic

Recycled plastic has the same properties as new plastic when it comes to strength. But there are also differences. For instance, bottles from R-HDPE are not (yet) suitable for foodstuffs or stay-on cosmetics applied to the skin.

In addition, there are a few superficial differences with regard to R-HDPE and R-PET. We use three types of recycled plastic: R-HDPE, R-PET and R-PP. Below you can find more info about recycled plastics: what they can be used for, how they are made, and how you can recognize them.

Looks

color

"Ivory"

You can see that I’ve been recycled by:

- The occasional speckle

- A light cleaner smell

Made of

Plastic waste from you, the consumer (e.g. from Plastic Heroes)

Suitable

- Suitable for cleaners, chemicals, plant food, hygiene, wash-off cosmetics etc.

- Labels, sleeves, or imprint

- Colouring (makes it slightly less recyclable)

Not suitable for

- Not suitable for foodstuffs or stay-on cosmetics.

Can be used for everything?

Unfortunately, recycled HDPE is not yet suitable for all products. This is because its origins are not 100% traceable. R-HDPE is therefore not suitable for foodstuffs, drinks and cosmetics applied to the skin, for example. But these bottles of R-HDPE are perfectly suitable for cleaning products, soap or plant food!

Ivory R-HDPE

Recycled HDPE is ivory coloured. This is because of the way sorting is done at the recycling plant QCP. Want a different colour or white? We can do it! Colouring can be added to the basic material. It makes a bit less environmentally friendly, but it is still a more environmentally friendly product than material that is not recycled.

Recognizing recycled plastic

- The speckle! There might be that a deviating spot on the packaging that would not be there if it was made of new plastic. This is the most important evidence that the packaging is recycled plastic.

- A light cleaner smell! This is from the recycling process. Usually this smell is masked by the fragrance of the product in the container.

Origins

Many new recycling factories have been built in recent years, which means that the origin is also different. Every factory has its strengths and let us choose the most suitable material for that production per product.

![]()

Looks

color

Transparent (with dark cast)

You can see that I've been recycled by:

- My slightly darker colour

Made of

Deposit (PET-) bottles

Suitable for

- Perfect for cleaners, chemicals, plant food, hygiene, wash-off cosmetics etc.

- Perfect for foodstuffs and stay-on cosmetics

- Labels, sleeves, or imprint

Can be used for everything?

For our R-PET we use the material MoPET, made from Dutch deposit bottles whose origins are therefore complete traceable. There are different levels of quality available, the best being MoPET-A, also suitable for foodstuffs, drinks and cosmetics.

Recognizing recycled plastic

Transparency! R-PET does not (yet) have the same transparency as new PET: there is a dark tinge. That means you can easily see that it’s recycled material!

The colour of R-PET is not (yet) 100% transparent, but it’s really close. Order a free sample packet here and see for yourself!

Origins

As we mentioned before, to make R-PET we use MoPET. This material is made from recycled deposit bottles collected in Dutch supermarkets.

![]()

Looks

Color

Grey / black

Origins

Plastic waste from you, the consumer (e.g. from Plastic Heroes)

Marketing Options

- Colour (testing phase)

Suitable for

- Perfect for cleaners, chemicals, plant food, hygiene, wash-off cosmetics etc.

Not suitable for

- Not suitable for foodstuffs or stay-on cosmetics.

Can be used for everything?

Just like R-HDPE, R-PP comes from the recycling company QCP in Limburg. So it’s made from Dutch waste! Caps made from recycled material are perfect for soap, cleaners, chemicals, plant food and wash-off cosmetics. Unfortunately it is not yet suitable for foodstuffs and stay-on cosmetics.

Recognizing recycled plastic

R-PP is grey when it comes from the recycling plant. You can of course give it a colour, but this makes it somewhat less environmentally friendly.

Origins

As we mentioned before, R-PP can be given a colour if you want to. Darker shades of blue, green and red can also be coloured black. We are still testing other colours to find out what the possibilities are.

Tips for a better plastic recycling flow

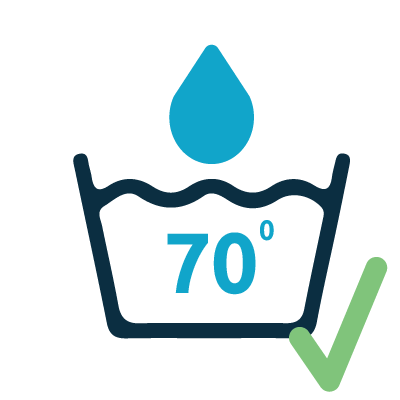

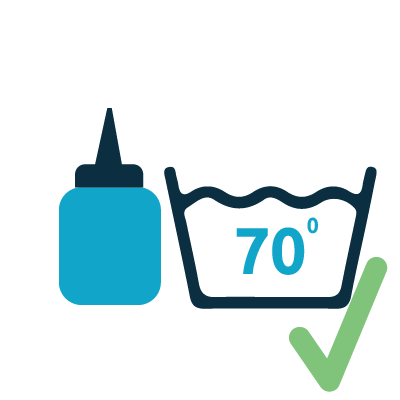

Imprints and colouring

Use ink that can be washed off at 70 degrees Celsius.

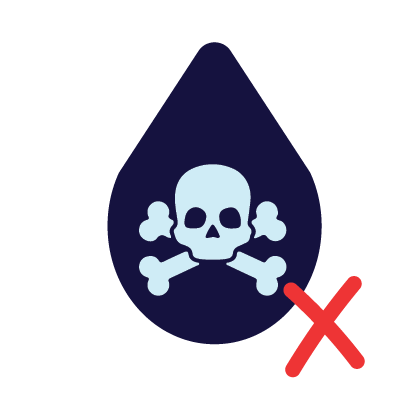

Do not use ink containing toxic substances.

Coloured plastic has some disadvantages when it comes to the recycling process. Remember: the purer it is, the purer the recycling flow.

Labels en sleeves

Preferably use the same material that the bottle has been made of.

Avoid a paper label, which is a nuisance in the plastic recycling flow.

Ensure that the glue holding the label dissolves at 70 degrees Celsius, so the label can be washed away.

Toxic substances

Do not use any silicon valves for the cap; the PP-valve is a great environmentally friendly option.

Do not use any opaque PET, i.e. PET that you can’t see through; this material may interfere with the recycling process.

Do we have to keep sorting waste at home?

Yes! Sometimes you hear that in some cases sorting waste at home isn’t better than sorting it at the waste treatment centre. This is only partially true. For now. The plastic chain is not yet 100% functional in all municipalities of the country, but this doesn’t mean that waste should not be sorted. The more the links in the chain dedicated to recycling, the better and more environmentally friendly the chain becomes.

Go to PlasticHeroes.nl for mor information

What goes in the plastic bin, and what doesn’t?

You can put all plastic packaging in the plastic bin, but there are a few exceptions.

Plastic products

The plastic bin is only for plastic packaging.

Black plastic

That means don’t collect plastic waste in a black bin bag; black plastic is not recognized as a recyclable material and will be incinerated, along with any contents.

Packaging of chemical products

Such as turpentine bottles and sealant containers. The packaging of multi-purpose cleaners, on the other hand, is acceptable.

Plastic with a metal layer

An aluminum lid, such as those used on margarine and yogurt containers, may sometimes be put in the plastic bin – it depends on the municipality.

Styrofoam

Such as fast-food containers or meat packages.

More information

Would you like to see what goes in the plastic bin, and what doesn’t? NOS (NL) has made a nice info-graphic that makes it all very clear. NOS Plastic Waste (NL)